- Time : Monday-Friday 09am-6pm

- Ceritified ( ISO 9001:2008 )

0982 0944 724 Quick CalL

Our Product Range

the leading stockiest, importers, exporters & suppliers of JFE 780 LE Plates

- Home

- Products

- High Tensile Plates

- JFE 780 LE Plates

JFE 780 LE Plates

High Strength JFE 780 LE Plates is low-alloyed high-strength steel plate manufactured by TMCP, or quenched and tempered. Because Champak offers high strength, it results in a significant reduction in the weight of welded structures. Good WeldabilityJFE 780 LE Plates of which chemical composition is controlled by specific procedure offers low carbon equivalent and excellent weldability.

Champak Industries also supplies welding materials suitable for JFE-HITEN effectively, and thereby enjoys acceptances by customers. Excellent Notch Toughness JFE 780 LE Plates offers high notch toughness because it is produced by closely controlling the chemical composition and heat treatment conditions. Application of Champak Industries ensures construction of structures providing high reliability against brittle fracture. Excellent Uniformity and Clean Surface Rolled on the most modern plate mill under rigid quality control, JFE 780 LE Plates has excellent uniformity in properties, flatness and surface finish. In addition, slab surfaces are carefully scarfed, powerful water jets are used during rolling, and nonoxidizing atmosphere furnaces are used for heat treatment. Consequently, JFE 780 LE Plates has smooth and clean surfaces. Good Workability Because JFE 780 LE Plates features good ductility, it offers not only good formability, but also good machinability, making it easy to drill and cut. Wide Range of Sizes JFE Plates are available in widths of up to 5,350mm, and in lengths of up to 27,000mm, and then contributes to saving expenses.

JFE'S HIGH TENSILE STRENGTH STEEL PLATE PRODUCTS SPECIFIED BY TYPICAL STANDARDS

| Type of Steel | JIS | ASTM | EN | WES ** | Ship's class Standard *** |

JFE Standard | |

| Steel Plates for Structural Use |

590N/mm2 Class | G 3106 SM570* | A678 Gr.0 Gr.D A841 |

HW 450 HW 450CF |

A47 D47 E47 F47 |

JFE-HITEN570U2 JFE-HITEN570E JFE-HITEN590S JFE-HITEN590SL JFE-HITEN590AZ JFE-HITEN590 JFE-HITEN590U2 JFE-HITEN590E |

|

| HW 490 HW 490CF |

A51 D51 E51 F51 |

JFE-HITEN610 JFE-HITEN610U2 JFE-HITEN610E |

|||||

| 690N/mm2 Class | HW 550 HW 620 |

A56 D56 E56 A63, 63N D63, 63N E63 |

JFE-HITEN690S JFE-HITEN690 JFE-HITEN690M JFE-HITEN710 JFE-HITEN710M |

||||

| 780N/mm2 Class | G 3128 SHY685 SHY685N SHY685NS |

A514 A709 Gr.100 |

HW 685 | A70, 70N D70, 70N E70, 70N F70, 70N |

JFE-HITEN780EX JFE-HITEN780S JFE-HITEN780LE JFE-HITEN780M |

||

| 980N/mm2 Class | HW 885 | JFE-HITEN980S JFE-HITEN980 |

|||||

| Steel Plates for Pressure Vessels |

590N/mm2 Class | G 3115 SPV450 G 3124 SEV345 |

A537 Cl. 2 A738 Gr.B A841 |

EN10028 P460N |

HW 450 | KPV46 | JFE-HITEN570U2 JFE-HITEN570E JFE-HITEN590 JFE-HITEN590U2 JFE-HITEN590E |

| G 3115 SPV490 | HW 490 | KPV50 | JFE-HITEN610 JFE-HITEN610U2 JFE-HITEN610E |

||||

| 690N/mm2 Class | A543 Cl. 1 | HW 620 | JFE-HITEN690M | ||||

| 780N/mm2 Class | A517 A543 Cl. 2 |

HW 685 | JFE-HITEN780M | ||||

| 980N/mm2 Class | HW 885 | JFE-HITEN980 | |||||

GRADES OF JFE-HITEN

| Strength (N/mm2) |

Designation | Thickness (mm) |

Yield Strength Min. (N/mm2) |

Tensile Strength (N/mm2) |

Features and Typical Applications |

| 590 | JFE-HITEN590 JFE-HITEN610 JFE-HITEN570U2 JFE-HITEN590U2 JFE-HITEN610U2 JFE-HITEN570E JFE-HITEN590E JFE-HITEN610E |

6 – 150 6 – 150 6 – 100 6 – 75 6 – 75 6 – 100 6 – 75 6 – 75 |

450 490 450 450 490 450 450 490 |

590 – 710 610 – 730 570 – 700 590 – 710 610 – 730 570 – 700 590 – 710 610 – 730 |

For Bridges, Penstocks, Tanks, Offshore structures U2 : High Tensile Strength Steel Plates with High Weldability E : High Tensile Strength Steel Plates with High Weldability for High Heat Input Welding |

| JFE-HITEN590S JFE-HITEN590SL |

6 – 40 6 – 50 |

450 450 |

590 – 710 590 – 710 |

S : Without Heat treatment for Civil Engineering and Industrial Machinery SL : Same as above with excellent toughness at low temperature (-40°C) |

|

| 690 | JFE-HITEN690 JFE-HITEN710 |

6 – 100 6 – 100 |

590 620 |

690 – 820 710 – 840 |

Ni-free type for Tanks, Offshore Structures etc. |

| JFE-HITEN690M JFE-HITEN710M |

6 – 100 6 – 100 |

590 620 |

690 – 820 710 – 840 |

Ni type and Low carbon-equivalent for Bridges, Penstocks, Tanks, etc. |

|

| JFE-HITEN690S | 6 – 25 | 550 | 690 – 830 | With reducing alloying elements and without Heat Treatment, for Civil Engineering and Industrial Machinery |

|

| 780 | JFE-HITEN780M | 6 – 150 | 685 | 780 – 930 | Ni type and Low Carbon-equivalent for Bridges, Penstocks, Offshore structures etc. |

| JFE-HITEN780EX | 6 – 60 | 685 | 780 – 930 | High Performance with Relaxing Pre-heating for Bridges |

|

| JFE-HITEN780S | 5 – 160 | 685 | 780 – 930 | Reducing alloying elements for Civil Engineering and Industrial Machinery |

|

| JFE-HITEN780LE | 5 – 160 160.1 – 203.2 |

685 610 |

780 – 930 700 – 850 |

High Weldability and excellent toughness at low temperature (-40°C), for Civil Engineering and Industrial Machinery |

|

| 980 | JFE-HITEN980 | 6 – 120 | 885 | 950 – 1130 | High Strength, High Weldability and Good Toughness for Penstocks |

| JFE-HITEN980S | 5 – 50.8 | 885 | 950 – 1130 | For Civil Engineering and Industrial Machinery | |

| JFE-HITEN980LE | 5 – 50.8 | 900 | 980 – 1150 | High tensile strength steel plate with excellent low temperature toughness (-40°C) for Civil Machinery and Industrial Machinery. |

|

| JFE–HYD960LE |

5 – 50.8 50.9 – 63.5 |

960 930 |

980 – 1150 950 – 1120 |

Higher yield strength than conventional 980 grade steel, high weldability and excellent toughness at low temperature (-40°C), for Civil Engineering and Industrial Machinery. |

|

| 1180 | JFE–HYD1100LE | 12 – 32 | 1100 | 1180 – 1500 | High tensile strength steel plate for Civil Machinery and Industrial Machinery. Has high yield stress, and excellent weldability and low temperature toughness (-40°C). |

AVAILABLE SIZES

Without Heat Treatment

| Width mm_ Thickness mm |

1000 _ 1400 |

1401 _ 1600 |

1601 _ 1800 |

1801 _ 2000 |

2001 _ 2200 |

2201 _ 2400 |

2401 _ 2600 |

2601 _ 2800 |

2801 _ 3000 |

3001 _ 3200 |

3201 _ 3400 |

3401 _ 3600 |

3601 _ 3800 |

3801 _ 4000 |

4001 _ 4200 |

4201 _ 4400 |

4401 _ 4600 |

4601 _ 4800 |

4801 _ 5000 |

5001 _ 5200 |

5201 _ 5300 |

5301 _ 5350 |

|

| 6.0 - 6.9 | 25 | 22 | 22 | 19 | 16 | 13.5 | 13.5 | ||||||||||||||||

| 7.0 - 9.0 | 22 | 20 | 16 | 13.5 | 13.5 | ||||||||||||||||||

| 9.1 - 11.9 | 20 | 20 | 20 | 16 | |||||||||||||||||||

| 12.0 - 13.9 | 27 | 25 | 22 | 16 | |||||||||||||||||||

| 14.0 - 25.0 | 16 | ||||||||||||||||||||||

| 25.1 - 28.0 | 25 | 16 | |||||||||||||||||||||

| 28.1 - 32.0 | 25 | 24 | 23 | 20 | 16 | ||||||||||||||||||

| 32.1 - 38.0 | 25 | 24 | 23 | 22 | 21 | 20 | 19 | 18 | 16 | ||||||||||||||

| 38.1 - 45.0 | 25 | 24 | 23 | 23 | 20 | 19 | 19 | 18 | 17 | 16 | 16 | 16 | |||||||||||

| 45.1 - 50.0 | 23 | 22 | 21 | 20 | 20 | 18 | 17 | 16 | 16 | 15 | 14 | 14 | 14 | ||||||||||

| 50.1 - 55.0 | 24 | 24 | 21 | 21 | 20 | 19 | 18 | 18 | 16 | 16 | 15 | 14 | 14 | 13 | 13 | 13 | |||||||

| 55.1 - 60.0 | 24 | 22 | 21 | 19 | 19 | 17 | 16 | 16 | 15 | 14 | 13 | 13 | 12 | 12 | 12 | 11 | |||||||

| 60.1 - 65.0 | 24 | 23 | 21 | 20 | 18 | 18 | 17 | 16 | 15 | 15 | 14 | 13 | 12 | 12 | 11 | 11 | 10 | 9.5 | |||||

| 65.1 - 70.0 | 24 | 24 | 22 | 21 | 19 | 18 | 17 | 16 | 15 | 14 | 14 | 13 | 12 | 12 | 11 | 11 | 10 | 10 | 9.5 | ||||

| 70.1 - 75.0 | 24 | 23 | 24 | 23 | 21 | 20 | 18 | 17 | 15 | 15 | 15 | 14 | 13 | 13 | 12 | 11 | 11 | 10 | 10 | 9.2 | 9 | 8.5 | |

| 75.1 - 80.0 | 23 | 23 | 22 | 21 | 21 | 19 | 18 | 17 | 15 | 14 | 14 | 13 | 12 | 12 | 11 | 11 | 10 | 10 | 9.6 | 9.2 | 9 | 8.5 | |

| 80.1 - 90.0 | 20 | 20 | 20 | 19 | 19 | 17 | 16 | 15 | 14 | 13 | 12 | 11 | 11 | 10 | 10 | 9.7 | 9.2 | 8.8 | 8.5 | 8.2 | 8 | 7.5 | |

| 90.1 - 100.0 | 18 | 18 | 18 | 17 | 17 | 15 | 14 | 13 | 12 | 11 | 11 | 10 | 10 | 9.6 | 9.1 | 8.7 | 8.3 | 8 | 7.6 | 7.3 | |||

| 100.1 - 110.0 | 16 | 16 | 16 | 16 | 15 | 14 | 13 | 12 | 11 | 10 | 10 | 9.7 | 9.1 | 9 | 8.3 | 8 | 7.6 | 7.2 | 7 | 6.7 5.8 |

|||

| 110.1 - 120.0 | 15 | 15 | 15 | 14 | 14 | 13 | 12 | 11 | 10 | 10 | 9.4 | 8.8 | 8.4 | 8 | 7.6 | 7.2 | 6.9 6.0 |

6.6 5.8 |

6 | 6 | |||

| 120.1 - 130.0 | 14 | 14 | 14 | 13 | 13 | 12 | 11 | 10 | 9.8 | 9.2 | 8.6 | 8.2 | 7.7 | 7.3 | 7.0 | 6.7 5.8 |

6 | 6 | 5.1 | 5.3 | |||

| 130.1 - 140.0 | 13 | 13 | 13 | 12 | 12 | 11 | 10 | 9.7 | 9 | 8.5 | 8 | 7.5 | 7.1 | 7 | 6 | 6 | 5.1 | 5.1 | 5.1 | 5.3 | |||

| 140.1 - 150.0 | 12 | 12 | 12 | 11 | 11 | 10 | 9.7 | 9.1 | 8.4 | 7.9 | 7.4 | 7 | 6.7 5.8 |

6 | 6 | 5 | 5 | 5 | |||||

Heat Treated

| Width mm_ Thickness mm |

1000 _ 1600 |

1601 _ 1800 |

1801 _ 2000 |

2001 _ 2200 |

2201 _ 2400 |

2401 _ 2600 |

2601 _ 2800 |

2801 _ 3000 |

3001 _ 3200 |

3201 _ 3400 |

3401 _ 3600 |

3601 _ 3800 |

3801 _ 4000 |

4001 _ 4200 |

4201 _ 4400 |

4401 _ 4600 |

4601 _ 4800 |

4801 _ 5000 |

5001 _ 5200 |

5201 _ 5300 |

5301 _ 5350 |

| 6.0 - 6.9 | 22 | 20 | 15 | 13 | |||||||||||||||||

| 7.0 - 7.9 | 25 | 24 | 22 | 20 | 15 | ||||||||||||||||

| 8.0 - 8.9 | 22 | 18 | 16 | 13 | 11 | ||||||||||||||||

| 9.0 - 9.9 | 22 | 20 | 16 | 12 | |||||||||||||||||

| 10.0 - 11.9 | 22 | 20 | 18 | Negotiable Range | |||||||||||||||||

| 12.0 - 13.9 | 22 | ||||||||||||||||||||

| 14.0 - 26.0 | |||||||||||||||||||||

| 26.1 - 28.0 | |||||||||||||||||||||

| 28.1 - 30.0 | 24 | 24 | 22 | ||||||||||||||||||

| 30.1 - 35.0 | 24 | 24 | 23 | 22 | 21 | 21 | 20 | ||||||||||||||

| 35.1 - 40.0 | 24 | 23 | 22 | 21 | 20 | 19 | 18 | 18 | 17 | ||||||||||||

| 40.1 - 45.0 | 23 | 22 | 20 | 19 | 19 | 18 | 17 | 16 | 16 | 15 | |||||||||||

| 45.1 - 50.0 | 23 | 22 | 20 17 |

19 | 18 | 17 | 17 | 16 | 15 | 15 | 14 | 14 11 |

|||||||||

| 50.1 - 60.0 | 24 | 24 | 22 | 20 | 19 | 18 | 16 | 15 | 14 | 14 | 13 | 13 | 12 | 11 | |||||||

| 60.1 - 70.0 | 23 | 20 | 24 | 22 | 20 | 19 | 17 | 16 | 15 | 14 | 14 | 13 | 12 | 12 | 11 | 11 | 10 | 10 | 10 | ||

| 70.1 - 80.0 | 22 | 20 | 18 | 21 | 19 | 18 | 16 | 15 | 14 | 13 | 13 | 12 | 11 | 11 | 10 | 10 | 9.7 | 9.3 | 8.9 | 8.7 | |

| 80.1 - 90.0 | 20 | 18 | 16 | 19 | 17 | 16 | 14 | 13 | 13 | 12 | 11 | 10 | 10 | 9.8 | 9.4 | 8.9 | 8.5 | 8.3 | 7.9 | ||

| 90.1 - 100.0 | 18 | 16 | 14 | 17 | 15 | 14 | 13 | 12 | 11 | 10 | 10 | 9.8 | 9.3 | 8.8 | 8.4 | 8.0 | 7.7 | 7.3 | 7.0 67 5.5 |

||

| 100.1 - 110.0 | 16 | 14 | 13 | 15 | 14 | 13 | 12 | 11 | 10 | 9.9 | 9.4 | 8.8 | 8.4 | 8.0 | 7.6 | 7.3 | 6, y 6.0 |

6.6 5.7 |

|||

| 110.1 - 120.0 | 15 | 13 | 12 | 14 | 13 | 11 | 11 | 10 | 9.7 | 9.1 | 8.5 | 8.1 | 7.7 | 7.3 | 6.9 6.0 |

6.6 5.7 |

6.3 5.8 |

5.2 | |||

| 120.1 - 130.0 | 13 | 12 | 11 | 13 | 11 | 11 | 10 | 9.5 | 8.9 | 8.3 | 7.9 | 7.3 | 7.0 | 6.7 | 6.4 5.5 |

5.2 | 5.0 | ||||

| 130.1 - 140.0 | 11 | 10 | 9.7 | 11 | 10 | 9.7 | 9.4 | 8.7 | 8.2 | 7.7 | 7.2 | 6.8 | 6.5 5.6 |

5.3 | 4.8 | ||||||

| 140.1 - 150.0 | 10 | 10 | 9.6 | 10 | 9.7 | 9.4 | 8.7 | 8.1 | 7.6 | 7.1 | 6.7 | 6.4 5.5 |

5.2 | 4.9 | |||||||

JFE-HITEN STANDARDS

JFE-HITEN590 Series and JFE-HITEN690 Series

| Designation (Thickness mm) |

Heat Treatment |

Chemical Composition (%) | Tensile Test*1) | Bending Test (180° ).2) | Charpy Impact Test (2mmV) *3) | ||||||||||||||||||||||

| C | Si | Mn | P | S | Cu | Ni | Cr | Mo | V | Nb | B | Ceq | PCM | Yield Strength | (N/mm2) | Tensile Strength (N/mm2) |

Elongation (%) |

Bending Radius | (Test Specimen No.1) | Test Temperature | (℃) | Absorbed Energy (J) | |||||

| Thickness (mm) |

Thickness (mm) |

Thickness (mm) |

Test Specimen |

Thickness (mm) |

Thickness (mm) | ||||||||||||||||||||||

| JFE-HITEN590 (6 - 150) |

QT | ≤ 0.16 | 0.15/0.55 | ≤ 1.50 | ≤ 0.025 | ≤ 0.015 | ≤ 0.30 | ≤ 1.00 | ≤ 0.30 | ≤ 0.30 | ≤ 0.08 | - | - | t ≤ 50 50< t ≤ 75 75< t |

≤ 0.44 ≤ 0.46 ≤ 0.48 |

≤ 0.26 ≤ 0.28 ≤ 0.28 |

- | ≥ 450 | 590/710 | t ≤ 16 16< t ≤ 50 20< t |

≥ 20 ≥ 28 ≥ 20 |

No.5 No.5 No.4 |

- | 1.5t | 12| - 10 |

≥ 47 |

|

| JFE-HITEN610 (6 - 150) |

QT | ≤ 0.16 | 0.15/0.55 | ≤ 1.50 | ≤ 0.025 | ≤ 0.015 | ≤ 0.30 | ≤ 1.00 | ≤ 0.30 | ≤ 0.30 | ≤ 0.08 | - | - | t ≤ 50 50< t ≤ 75 75< t |

≤ 0.45 ≤ 0.47 ≤ 0.49 |

≤ 0.26 ≤ 0.28 ≤ 0.28 |

t ≤ 75 75< t |

≥ 490 ≥ 470 |

610/730 | t ≤ 16 16< t ≤ 50 20< t |

≥ 19 ≥ 27 ≥ 19 |

No.5 No.5 No.4 |

-; | 1.5t | 12| - 10 |

- 15 ≥ 47 |

≥ 47 |

| JFE-HITEN690 (6 - 100) |

QT | ≤ 0.16 | ≤ 0.35 | ≤ 1.20 | ≤ 0.025 | ≤ 0.015 | ≤ 0.40 | ≤ 1.00 | ≤ 0.70 | ≤ 0.50 | ≤ 0.08 | - | ≤ 0.005 | t ≤ 50 50< t |

≤ 0.54 ≤ 0.58 |

- - |

t ≤ 75 75< t | ≥ 590 ≥ 570 |

690/820 | t ≤ 16 16< t ≤ 50 20< t |

≥ 17 ≥ 25 ≥ 17 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t 2.0t |

12| - 15 |

- 20 - 30 ≥ 47 |

≥ 47 ≥ 47 |

| JFE-HITEN710 (6 - 100) |

QT | ≤ 0.16 | ≤ 0.35 | ≤ 1.20 | ≤ 0.025 | ≤ 0.015 | ≤ 0.40 | ≤ 1.00 | ≤ 0.70 | ≤ 0.50 | ≤ 0.08 | - | ≤ 0.005 | t ≤ 50 50< t |

≤ 0.55 ≤ 0.59 |

- - |

t ≤ 75 75< t |

≥ 620 ≥ 600 |

710/840 | t ≤ 16 16< t ≤ 50 20< t |

≥ 17 ≥ 25 ≥ 17 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t . 20t |

12| -15 |

- 20 - 30 ≥ 47 |

≥ 47 ≥ 47 |

| JFE-HITEN690M (6 - 100) |

OT | ≤ 0.14 | ≤ 0.35 | ≤ 1.20 | ≤ 0.015 | ≤ 0.015 | ≤ 0.40 | 0.30/1.30 | ≤ 0.70 | ≤ 0.50 | ≤ 0.05 | - | ≤ 0.005 | t ≤ 50 50< t |

≤ 0.53 ≤ 0.57 |

- - |

t ≤ 75 75< t |

≥ 590 ≥ 570 |

690/820 | t ≤ 16 16< t ≤ 50 20< t |

≥ 17 ≥ 25 ≥ 17 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t . 20t |

12| - 15 |

- 20 - 30 ≥ 47 |

≥ 47 ≥ 47 |

| JFE-HITEN710M (6 - 100) |

QT | ≤ 0.14 | ≤ 0.35 | ≤ 1.20 | ≤ 0.015 | ≤ 0.015 | ≤ 0.40 | 0.30/1.30 | ≤ 0.70 | ≤ 0.50 | ≤ 0.05 | - | ≤ 0.005 | t ≤ 50 50< t |

≤ 0.53 ≤ 0.57 |

- - |

t ≤ 75 75< t |

≥ 620 ≥ 600 |

710/840 | t ≤ 16 16< t ≤ 50 20< t |

≥ 17 ≥ 25 ≥ 17 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t . 20t |

12| - 15 |

- 20 - 30 ≥ 47 |

≥ 47 ≥ 47 |

JFE-HITEN780 Series and JFE-HITEN980

| Designation (Thickness mm) |

Heat Treatment |

Chemical Composition (%) | Tensile Test*1) | Bending Test (180° ).2) | Charpy Impact Test (2mmV) *3) | |||||||||||||||||||||||

| Thickness (mm) |

C | Si | Mn | P | S | Cu | Ni | Cr | Mo | V | Nb | B | Ceq | PCM | Yield Strength | (N/mm2) | Tensile Strength (N/mm2) |

Elongation (%) |

Bending Radius | (Test Specimen No.1) | Test Temperature | (℃) | Absorbed Energy (J) | |||||

| Thickness (mm) |

Thickness (mm) |

Thickness (mm) |

Test Specimen |

Thickness (mm) |

Thickness (mm) | |||||||||||||||||||||||

| JFE-HITEN780M (6-150) |

QT | t≤ 100 100 ≤ 0.14 |

≤ 0.18 ≤ 0.35 |

≤ 0.35 ≤ 1.20 |

≤ 1.20 ≤ 0.015 |

≤ 0.015 ≤ 0.015 |

≤ 0.015 ≤ 0.50 |

≤ 0.50 0.30/1.50 |

0.30/1.50 ≤ 0.70 |

≤ 0.80 ≤ 0.60 |

≤ 0.60 ≤ 0.05 |

≤ 0.05 - |

- ≤ 0.005 |

≤ 0.005 t ≤ 50 |

50< t ≤ 100 100< t ≤ 0.53 |

≤ 0.57 ≤ 0.62 ≤ 0.30 |

≤ 0.32 ̶ t ≤ 75 |

75< t ≥ 685 |

≥ 665 780/930 |

t< 16 |

16< t < 50 20< t > 16 |

≥ 24 ≥ 16 No.5 |

No.5 No.4 t < 32 32< t |

1.5t |

2.0t 12<t < 32 32<t < 50 50<t |

-20 |

- 25 - 35 ≥ 47 |

≥ 47 ≥ 47 |

| JFE-HITEN980 (6 - 120) |

OT | - | ≤ 0.14 | ≤ 0.35 | ≤ 1.20 | ≤ 0.010 | ≤ 0.005 | ≤ 0.70 | ≤ 4.00 | ≤ 0.80 | ≤ 0.80 | ≤ 0.15 | ≤ 0.02 | ≤ 0.005 | t ≤ 50 50< t ≤ 100 100< t |

≤ 0.59 ≤ 0.62 ≤ 0.71 |

≤ 0.29 ≤ 0.33 ≤ 0.36 |

t ≤ 75 75< t ≤ 100 100< t |

≥ 885 ≥ 865 ≥ 865 |

950/1130 950/1130 930/1110 |

t ≤ 16 16< t ≤ 50 20< t |

≥ 12 ≥ 19 ≥ 12 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

2.0t 2.5t |

12| - 60 |

≥ 47 |

|

High Tensile Strength Steel Plates with Good Weldability

| Designation (Thickness mm) |

Heat Treatment |

Chemical Composition (%) | Tensile Test*1) | Bending Test (180° ).2) | Charpy Impact Test (2mmV) *3) | ||||||||||||||||||||||

| C | Si | Mn | P | S | Cu | Ni | Cr | Mo | V | Nb | B | Ceq | PCM | Yield Strength | (N/mm2) | Tensile Strength (N/mm2) |

Elongation (%) |

Bending Radius | (Test Specimen No.1) | Test Temperature | (℃) | Absorbed Energy (J) | |||||

| Thickness (mm) |

Thickness (mm) |

Thickness (mm) |

Test Specimen |

Thickness (mm) |

Thickness (mm) | ||||||||||||||||||||||

| JFE - HITEN570U2 (6 – 100) |

QT | ≤ 0.09 | 0.15/0.55 | ≤ 1.60 | ≤ 0.025 | ≤ 0.010 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.06 | ≤ 0.03 | - | - | - | ≤ 0.20 | t ≤ 16 16< t ≤ 40 40< t ≤ 75 75< t |

≥ 460 ≥ 450 ≥ 430 ≥ 420 |

570/700 | t ≤ 16 16< t ≤ 50 20< t |

≥ 20 ≥ 28 ≥ 20 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t 2.0t |

12< t | - 5 | ≥ 47 |

| JFE - HITEN590E (6 – 75) |

QT | ≤ 0.09 | 0.15/0.55 | 1.00/1.60 | ≤ 0.020 | ≤ 0.010 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.06 | ≤ 0.03 | - | - | - | ≤ 0.20 | - | ≥ 450 | 590/710 | t ≤ 16 16< t ≤ 50 20< t |

≥ 20 ≥ 28 ≥ 20 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t 2.0t |

6≤ t ≤ 20 20< t ≤ 32 32< t ≤ 50 50< t |

5 - 5 - 10 - 20 |

≥ 47 ** ≥ 47 ≥ 47 ≥ 47 |

| JFE - HITEN610E (6 – 75) | QT | ≤ 0.09 | 0.15/0.55 | 1.20/1.60 | ≤ 0.025 | ≤ 0.010 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.06 | ≤ 0.03 | - | - | - | ≤ 0.20 | - | ≥ 490 | 610/730 | t ≤ 16 16< t ≤ 50 20< t |

≥ 19 ≥ 27 ≥ 19 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t 2.0t |

6≤ t ≤ 20 20< t ≤ 32 32< t ≤ 50 50< t |

0 - 5 - 15 - 25 |

≥ 47 ** ≥ 47 ≥ 47 ≥ 47 |

| JFE - HITEN780EX (6 – 60) |

QT | ≤ 0.09 | ≤ 0.55 | 0.60/1.50 | ≤ 0.015 | ≤ 0.010 | ≤ 0.50 | 0.30/1.50 | ≤ 0.80 | ≤ 0.60 | ≤ 0.05 | ≤ 0.03 | ≤ 0.005 | t ≤ 34 34< t ≤ 60 |

≤ 0.53 * ≤ 0.57 * |

≤ 0.23 ≤ 0.25 |

t ≤ 50 50< t ≤ 60 |

≥ 685 ≥ 665 |

780/930 760/910 |

t ≤ 16 16< t ≤ 50 20< t |

≥ 16 ≥ 24 ≥ 16 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t 2.0t |

12< t ≤ 32 32< t ≤ 60 |

- 20 - 25 |

≥ 47 ≥ 47 |

High Tensile Strength Steel Plates for High Heat-input Welding

| Designation (Thickness mm) |

Heat Treatment |

Chemical Composition (%) | Tensile Test*1) | Bending Test (180° ).2) | Charpy Impact Test (2mmV) *3) | ||||||||||||||||||||

| C | Si | Mn | P | S | Cu | Ni | Cr | Mo | V | Nb | B | PCM | Yield Strength | (N/mm2) | Tensile Strength (N/mm2) |

Elongation (%) |

Bending Radius | (Test Specimen No.1) | Test Temperature | (℃) | Absorbed Energy (J) | ||||

| Thickness (mm) |

Thickness (mm) |

Thickness (mm) |

Test Specimen |

Thickness (mm) |

|||||||||||||||||||||

| JFE - HITEN570E (6 – 100) | QT | ≤ 0.09 | 0.15/0.55 | ≤ 1.60 | ≤ 0.020 | ≤ 0.010 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.06 | ≤ 0.03 | - | ≤ 0.20 | t ≤ 16 16< t ≤ 40 40< t ≤ 75 75< t |

≥ 460 ≥ 450 ≥ 430 ≥ 420 |

570/700 | t ≤ 16 16< t ≤ 50 20< t |

≥ 20 ≥ 28 ≥ 20 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t 2.0t |

12< t | - 5 | ≥ 47 |

| JFE - HITEN590E (6 – 75) | QT | ≤ 0.09 | 0.15/0.55 | 1.00/1.60 | ≤ 0.020 | ≤ 0.010 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.06 | ≤ 0.03 | - | ≤ 0.20 | - | ≥ 450 | 590/710 | t ≤ 16 16< t ≤ 50 20< t |

≥ 20 ≥ 28 ≥ 20 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t 2.0t |

6≤ t ≤ 20 20< t ≤ 32 32< t ≤ 50 50< t |

5 - 5 - 10 - 20 |

≥ 47** ≥ 47 ≥ 47 ≥ 47 |

| JFE - HITEN610E (6 – 75) | QT | ≤ 0.09 | 0.15/0.55 | 1.00/1.60 | ≤ 0.020 | ≤ 0.010 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.06 | ≤ 0.03 | - | ≤ 0.20 | - | ≥ 490 | 610/730 | t ≤ 16 16< t ≤ 50 20< t |

≥ 19 ≥ 27 ≥ 19 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t 2.0t |

6≤ t ≤ 20 20< t ≤ 32 32< t ≤ 50 50< t |

0 - 5 - 15 - 25 |

≥ 47** ≥ 47 ≥ 47 ≥ 47 |

High Tensile Strength Steel Plates for Civil Engineering and Industrial Machinery

| Designation (Thickness mm) |

Heat Treatment |

Chemical Composition (%) | Tensile Test*1) | Bending Test (180° ).2) | Charpy Impact Test (2mmV) *3) | ||||||||||||||||||||||

| Thickness (mm) |

C | Si | Mn | P | S | Cu | Ni | Cr | Mo | V | Nb | B | Ceq | PCM | Yield Strength | (N/mm2) | Tensile Strength (N/mm2) |

Elongation (%) |

Bending Radius | (Test Specimen No.1) | Test Temperature | (℃) | Absorbed Energy (J) | ||||

| Thickness (mm) |

Thickness (mm) |

Thickness (mm) |

Test Specimen |

Thickness (mm) |

|||||||||||||||||||||||

| JFE - HITEN590SA (6 – 40) | CR or TMCP | - | ≤ 0.18 | ≤ 0.55 | ≤ 2.00 | ≤ 0.030 | ≤ 0.020 | Other elements are added as required. | ≤ 0.45 | - | - | ≥ 450 | 590/710 | t ≤ 16 16< t ≤ 50 20< t |

≥ 20 ≥ 28 ≥ 20 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t 2.0t |

- | - | - | ||||||

| JFE - HITEN590SB (6 – 40) | - | ≤ 0.18 | ≤ 0.55 | ≤ 2.00 | ≤ 0.030 | ≤ 0.015 | Other elements are added as required. | ≤ 0.45 | - | 12< t | - 10 | ≥ 47 | |||||||||||||||

| JFE - HITEN590SL(6 – 50) | CR or TMCP | - | ≤ 0.16 | 0.20/0.55 | 0.80/1.60 | ≤ 0.030 | ≤ 0.015 | - | - | - | ≤ 0.35 | ≤ 0.08 | ≤ 0.05 | - | ≤ 0.46 | ≤ 0.22 | t ≤ 32 32< t | ≥ 450 ≥ 430 |

590/710 570/705 |

t ≤ 16 16< t ≤ 20 20< t |

≥ 20 ≥ 26 ≥ 20 |

No.5 No.5 No.4 |

- | 1.5t | 6 ≤ t ≤ 36 36< t |

- 40 - 20 |

≥ 27 ** ≥ 27 |

| JFE - HITEN690S(6 – 25) | CR or TMCP | - | ≤ 0.15 | ≤ 0.55 | ≤ 2.00 | ≤ 0.030 | ≤ 0.015 | Other elements such as Nb, V and Ti are added as required. | ≤ 0.50 | - | - | ≥ 550 | 690/830 | t ≤ 16 16< t |

≥ 17 ≥ 25 |

No.5 No.5 |

- | 1.5t | 12< t | - 10 | ≥ 47 | ||||||

| JFE - HITEN780S (5 – 160) | QT | t ≤ 50 | ≤ 0.25 | ≤ 0.55 | ≤ 1.60 | ≤ 0.030 | ≤ 0.015 | - | - | ≤ 0.70 | ≤ 0.30 | ≤ 0.10 | Ti:0.005/0.02 | ≤ 0.005 | ≤ 0.53 | - | t ≤ 75 75< t ≤ 160 |

≥ 685 ≥ 665 |

780/930 780/930 |

t ≤ 16 16< t ≤ 32 20< t |

≥ 16 ≥ 24 ≥ 16 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t 2.0t |

5≤ t ≤ 12 12< t ≤ 20 20< t ≤ 32 32< t ≤ 160 |

- - 5 - 15 - 20 |

- ≥ 35 ≥ 35 ≥ 35 |

| 50< t ≤ 100 | ≤ 0.20 | ≤ 0.50 | ≤ 0.50 | ≤ 1.50 | ≤ 0.60 | Ti:0.005/0.02 | ≤ 0.61 | ||||||||||||||||||||

| 100< t ≤ 160 | ≤ 0.18 | ≤ 0.50 | ≤ 0.50 | ≤ 1.50 | ≤ 0.60 | Ti: ≤ 0.03 | ≤ 0.70 | ||||||||||||||||||||

| JFE - HITEN780LE(5 – 203.2) | QT or TMCP | t ≤ 19 19< t ≤ 32 32< t ≤ 50 50< t ≤ 70 70< t ≤ 160 160< t ≤ 203.2 |

≤ 0.20 | ≤ 0.40 | ≤ 1.40 | ≤ 0.025 | ≤ 0.015 | - | - | ≤ 0.20 | ≤ 0.15 | ≤ 0.08 | ≤ 0.03 | ≤ 0.005 | ≤ 0.40* | - | - | ≥ 685 | 780/930 | t ≤ 16 16< t ≤ 40 20< t |

≥ 16 ≥ 24 ≥ 16 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

1.5t 2.0t |

5≤ t < 6 6≤ t < 12 12≤ t ≤ 160 160< t ≤ 203.2 |

— - 40 - 40 - 40 |

— ≥ 40 *** ≥ 40 ≥ 35 |

| ≤ 0.43* | |||||||||||||||||||||||||||

| ≤ 0.80 | ≤ 0.40 | ≤ 0.53* | |||||||||||||||||||||||||

| ≤ 0.65* | |||||||||||||||||||||||||||

| ≤ 0.18 | ≤ 1.50 | ≤ 0.80 | ≤ 0.10 | ≤ 0.73* | |||||||||||||||||||||||

| ≤ 0.18 | ≤ 0.55 | ≤ 1.60 | ≤ 0.60 | ≤ 0.75 | ≤ 1.50 | ≤ 0.80 | ≤ 0.10 | Ti: ≤ 0.03 | ≤ 0.78* | 160< t ≤ 203.2 | ≥ 610 | 700/850 | |||||||||||||||

| JFE - HITEN980S(5 – 50.8) | QT | - | ≤ 0.18 | ≤ 0.35 | ≤ 1.20 | ≤ 0.020 | ≤ 0.020 | ≤ 0.70 | ≤ 2.00 | ≤ 0.80 | ≤ 0.80 | ≤ 0.08 | ≤ 0.02 | ≤ 0.005 | ≤ 0.65 | - | - | ≥ 885 | 950/1130 | t ≤ 16 16< t ≤ 50.8 20< t |

≥ 12 ≥ 19 ≥ 12 |

No.5 No.5 No.4 |

t ≤ 32 32< t |

2.0t 2.5t |

5≤ t ≤ 12 12< t ≤ 20 20< t ≤ 32 32< t |

— - 10 - 25 - 30 |

— ≥ 35 ≥ 35 ≥ 35 |

| JFE - HITEN980LE (5 – 50.8) | QT | t ≤ 32 32< t ≤ 50.8 | ≤ 0.18 | ≤ 0.40 | ≤ 1.40 | ≤ 0.020 | ≤ 0.015 | - | - | ≤ 0.80 ≤ 1.50 |

≤ 0.60 ≤ 0.80 |

≤ 0.10 | ≤ 0.03 | ≤ 0.005 | ≤ 0.58* ≤ 0.65* |

- | - | ≥ 900 | 980/1150 | t ≤ 16 16< t ≤ 50.8 20< t |

≥ 12 ≥ 19 ≥ 12 |

No.5 No.5 No.4 |

t ≤ 32 32< |

2.0t 2.5t | 5≤ t < 6 6≤ t < 12 12≤ t < 50.8 |

— - 40 - 40 |

— ≥ 40 *** ≥ 40 |

| JFE – HYD960LE (5 – 63.5) | QT or TMCP | t ≤ 32 | ≤ 0.18 | ≤ 0.70 | ≤ 1.70 | ≤ 0.020 | ≤ 0.010 | - | - | ≤ 1.00 | ≤ 0.60 | ≤ 0.08 | - | ≤ 0.004 | ≤ 0.64* | - | t ≤ 50.8 | ≥ 960 | 980/1150 | t ≤ 40 40< t |

≥ 12 | No.5 No.4 |

- | 3.0t | 5≤ t < 6 6≤ t ≤ 63.5 |

— - 40 |

— ≥ 27**** |

| 32< t ≤ 50.8 | ≤ 0.20 | ≤ 0.90 | ≤ 0.70* | ||||||||||||||||||||||||

| 50.8< t ≤ 63.5 | 50.8< t ≤ 63.5 | ≥ 930 | 950/1120 | ||||||||||||||||||||||||

| JFE – HYD1100LE (12 – 32) | TMCP | - | ≤ 0.20 | ≤ 0.70 | ≤ 1.70 | ≤ 0.020 | ≤ 0.010 | - | - | — ≤ 1.00 | ≤ 0.90 | ≤ 0.08 | - | ≤ 0.004 | ≤ 0.70* | - | - | ≥ 1100 | 1180/1500 | - | ≥ 12 | No.5 | - | 4.0t | - | - 40 | ≥ 27 |

Dimensional Tolerance, Shape, and Appearance

| Designation | Dimensional Tolerance, Shape, and Appearance |

| 590, 590U2, 590E 610, 610U2, 610E 690, 690M, 710, 710M 780M 980 |

Dimensional tolerances of thickness, width, and length, flatness, and shape are in accordance with JIS G 3115. |

| 570U2, 570E 590S, 590SL 690S 780S, 780LE, 780EX 980S, 980LE, HYD960LE, HYD1100LE |

Dimensional tolerances of thickness, width, and length, flatness, and shape are in accordance with JIS G 3193. |

TYPICAL PROPERTIES OF JFE-HITEN

JFE-HITEN 610U2 ─ 590N/mm2 Class High Tensile Strength

Steel Plates with good Weldability

Chemical composition

Chemical composition

| Designation | Th ic (mmkne)ss |

C | Si | Mn | P | S | Pcm |

| JFE-HITEN610U2 | 75 | 0.08 | 0.26 | 1 44 | 0.005 | 0.002 | 0.18 |

| Conventional 590N/mm2g rade | 50 | 0.13 | 0.26 | 1.29 | 0.011 | 0.003 | 0.23 |

Mechanical properties of plate

| Designation | Tensile test | Charpy impact test | ||||

| YS (N/mm2) |

TS (N/mm2) |

El* (%) |

Temp. (t) |

Dir. | Absorbed energy (J) |

|

| JFE-HITEN610U2 | 534 | 624 | 31* | - 10 | L | 275 |

| Conventional 590N/mm2g rade | 566 | 668 | 50 | - 10 | L | 269 |

JFE-HITEN 610E ─ 590N/mm2 Class High Tensile Strength Steel Plates for High Heat-input Welding

Chemical composition

| Designation | Th ic (mmkne)ss |

C | Si | Mn | P | S | Pcm |

| JFE-HITEN610E | 25 | 0.08 | 0.20 | 1.33 | 0.008 | 0.003 | 0.17 |

Mechanical properties of electro-gas arc welded joint

| Welding condition | Tensile strength of welded joint (N/mm2) |

Charpy impact test | ||||

| Groove configuration | Welding material | Heat input (kJ/mm) |

Test location | Test temp. (°C) |

Absorbed energy (J) |

|

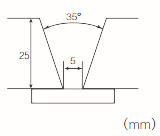

|

DWS–1LG | 120 | 617 618 |

Weld metal | 0 | 113 |

| - 25 | 82 | |||||

| Fusion line | 0 | 244 | ||||

| - 25 | 171 | |||||

| Center of HAZ | 0 | 271 | ||||

| - 25 | 171 | |||||

JFE-HITEN 780EX ─ 780N/mm2 Class High Tensile Strength Steel Plates with High Weldability

Chemical composition

| Designation | Thickness (mm) | C | Si | Mn | P | S | Pcm |

| JFE-HITEN780EX | 34 | 0.08 | 0.20 | 1.05 | 0.004 | 0.001 | 0.22 |

Mechanical properties of plate

| Tensile test | Charpy impact test | ||||

| YS | TS | El* | Temp. | Dir. | Absorbed energy |

| (N/mm2) | (N/mm2) | (%) | (°C) | (J) | |

| 769 | 844 | 24 | - 40 | L | 286 |

JFE-HITEN 980 ─ 980N/mm2 Class High Tensile Strength Steel Plates with High Weldability

Chemical composition

| Thickness (mm) | C | Si | Mn | P | S | Pcm |

| 75 | 0.09 | 0.25 | 1.14 | 0.005 | 0.001 | 0.27 |

Mechanical properties of plate

| Tensile test(1/4 t) | Charpy impact test(1/4 t) | ||||

| YS | TS | El* | Temp. | Dir. | Absorbed energy |

| (N/mm2) | (N/mm2) | (%) | (°C) | (J) | |

| 930 | 977 | 25 | 0 | C | 208 |

| - 60 | C | 158 | |||

Mechanical properties of submerged arc welded joint

| Welding condition | Tensile strength of welded joint (N/mm2) |

Charpy impact test | ||||

| Groove configuration | Welding material | Heat input (kJ/mm) |

Test location | Test temp. (t) |

Absorbed energy (J) |

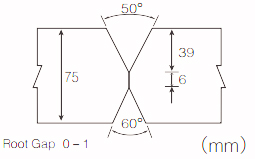

|

|

PFH-100J/US -100J |

45 | 977 981 |

Weld metal | - 10 | 109 |

| Fusion line | 136 | |||||

| Center of HAZ | 248 | |||||